Make Toyota Model: 4A-FE

Notice: Be careful of moving parts on the engine when you do these tests.

If vehicle is diesel or hybrid that contains high voltage, it can kill you.

Check with your lecturer before testing.

If you have problems with the task, see you lecturer for help.

1.0 Battery Voltage to Injectors (Warning: Petrol Vehicles Only. Some diesels will have dangerously high voltage to fuel injectors.)

1.1 Locate a fuel injector

1.2 Back-probe the wire to the fuel injector by inserting a pin down the rubber insulation far enough to connect with the metal wire terminal on the inside.

Don’t puncture or damage the wiring. Hook up your multimeter red lead to read dc volts. Make sure the meter black lead is grounded.

1.3 Make sure students and meter leads are clear of moving parts, and start the engine.

1.4 Record the voltage to the fuel injector:14.04V

Discuss why would we bother checking the voltage supply to the fuel injectors?

For make sure the battery enough supply voltage to the injectors.

1.5 If we find lower voltage at the injectors than at the battery, what can that mean? And how would injector operation be affected?

May be there is resistance in connection between battery and injectors. The injector cannot fully open or open properly and effect of the spraying injector to combustion engine.

Because the injector is a solenoid with grounding trigger where is the battery always supply voltage to the injector. ECU just switch on or off the transistor to close open the injectors. When the current is going through to the coil inside the injector, the injector will be open and spraying the fuel.

1.6 Draw a full circuit diagram for the fuel injectors, including battery ,ignition switch, main relay:

2.0 Reference Voltage at TPS sensor

2.1 Find the TPS sensor. Locate the likely 5V Reference wire at the TPS sensor. (You may have to try several wires before you get a good reading)

2.2 Back-probe the wire to the TPS sensor by inserting a pin down the rubber insulation far enough to connect with the metal wire terminal on the inside.

Don’t puncture or damage the wiring. Hook up your multimeter red lead to read dc volts. Make sure the meter black lead is grounded.

2.3 Make sure all students and meter leads are clear of the engine. Turn the ignition “on”, but don’t start the engine.

Is this an acceptable or unacceptable reading? If you do not get the correct reading on the meter, you may have to check for a good connection, or try another wire until you get a good reading to record above.

2.5 What is the purpose of the reference voltage to the throttle position sensor?

Reference voltage is voltage supply from ECU. Signal back as voltage from TPS sensor to ECU depends on the angle open throttle. The voltage changes on TPS sensor because the resistance inside. By sending back voltage to the ECU, ECU will know how much air and fuel needs.

2.6 What could cause problems so that there is not the correct reference voltage at the throttle position sensor?

If there is not correct reference may because the wire corroded or bad earth. And low voltage because connected to the ground.

Ground at TPS sensor

3 Locate the ground or earth wire at a TPS sensor

3.1 Back-probe the sensor ground or earth wire by inserting a pin down the rubber insulation far enough to connect with the metal wire terminal on the inside. Don’t puncture or damage the wiring. Hook up your multimeter red lead to read dc volts. Set the meter range or scale to 4V or less. Make sure the meter black lead is grounded on engine block or battery.

3.2 Make sure students and meter leads are clear of moving parts, and start the engine.

3.3 Record the voltage on the meter: 0.0085V (A good ground will usually read less than 0.05V. Some manufacturers say 0.10V.)

3.3 What does this voltage tell you about the ECU earth or ground? Why is it important to measure it?

The voltage 0.0085V which is good, less than 0.o5V. Because very small voltage means not much resistance may be we can ignored and the TPS will be working properly.

3.4 Discuss what could go wrong so that the ECU earth or ground is not good:

The TPS will tell ECU wrong signal and engine could be running rich, black smoke and high emission.

Throttle Position Sensor return/output:

For vehicles that have a linear type sensor with a potentiometer only.

For vehicles that have only switches, see the next section.

4.0 With the engine NOT running, back-probe a likely wire for the TPS input by inserting a pin down the rubber insulation far enough to connect with the metal wire terminal on the inside. Do not damage the wiring. Set up the voltmeter to read DC Volts. Attach meter red lead to the pin; attach black lead to a good ground.

4.1 Make sure all students are clear of the engine. Turn the ignition “on”, but don’t start the engine.

4.9 Describe problems which could occur to prevent the TPS from sending the

4.2 Record the reading from the meter: 0.37V. If you do not get a reading on the meter, you may have to check for a good connection, or try different wires until you get a good reading to record above.

4.3 Open the throttle to about the half open position, (make sure engine is not running) and record the reading on the meter: 2.050V Close the throttle.

4.4 Open the throttle to the full open position, (make sure engine is not running), and record the reading on the meter: 3.67V

4.5 Slowly open the throttle from the closed position to the full open position, and watch that the meter readings slowly increase with no sudden jumps or gaps in the signal. OK

4.6 If your vehicle has four wires going to the TPS sensor, continue with these next steps to read the idle switch circuit. Locate the idle switch wire. It will usually read about 0V when the throttle is closed, and 12 – 14V when the throttle is opened. Back probe the different wires until you locate the wire that gives these DC Volt readings. Record the color of this wire: Blue

4.7 Describe how a TPS sensor works.

The TPS I tested has 4 pins terminal which Vcc is input voltage, VTA is signal voltage send to ECU and IDL connect to ECU as well.

If we look the picture below, there are 4 paths, 2 paths on the top and the 2 paths on bottom. There is 1 contact on the top connected pins between Vcc and VTA and the other contact on the bottom connected IDL and ground. VTA pin is for open throttle signal and IDL pin is for close throttle signal both of these send to ECU. When the throttle or butterfly is moving the4 paths moving to because they are the same axle. Input of 5V will change when the throttle butterfly is moving, the output voltage depends on angle of butterfly. When throttle close , idle contact is close and when throttle open the contact idle will be open and the voltage starting low to high. At idle position there will be low voltage and telling the ECU that need small amount of petrol coming through to the engine because less air; at full throttle position there will be high voltage and telling the ECU supply more petrol to the engine. Voltage output depends on the potentiometer.

If we look the picture below, there are 4 paths, 2 paths on the top and the 2 paths on bottom. There is 1 contact on the top connected pins between Vcc and VTA and the other contact on the bottom connected IDL and ground. VTA pin is for open throttle signal and IDL pin is for close throttle signal both of these send to ECU. When the throttle or butterfly is moving the4 paths moving to because they are the same axle. Input of 5V will change when the throttle butterfly is moving, the output voltage depends on angle of butterfly. When throttle close , idle contact is close and when throttle open the contact idle will be open and the voltage starting low to high. At idle position there will be low voltage and telling the ECU that need small amount of petrol coming through to the engine because less air; at full throttle position there will be high voltage and telling the ECU supply more petrol to the engine. Voltage output depends on the potentiometer.

4.8 Discuss what type of sensor voltages should go to the ECU as the throttle is opened and closed:

When the throttle is opened, the signal arm moves up on the carbon track and therefore decrease in resistance and the voltage will be increased. When the throttle is closed, the resistance is highest and voltage is going low.

4.9 Describe problems which could occur to prevent the TPS from sending the

correct voltage to the ECU:

Could be bad ground because corroded, high resistance because the sludge on the track and possible of input voltage reference below 0.5V.

4.9 Draw a full circuit diagram for the TPS on this vehicle:

Throttle Position Switch

5.1 Locate the TPS on your vehicle. Tested on the old Nissan Engine.

5.2 Back probe the wires to the TPS with the ignition on but engine not running. Open and close the throttle with the meter connected, and locate which wire has the voltage which changes at idle, and which wire has the voltage which changes near wide open throttle. Record wire colors and voltages below.

Idle wire: Color: Black.

Volts at Idle 0.08V.

Volts at part throttle or open throttle: 10.70V.

Wide Open Throttle wire: Color: Black.

Volts at idle or part throttle: 10.24V.

Volts at open throttle: 0V.

5.3 By watching the voltages above, figure out the circuit diagram for this TPS, and draw it in the box below. You may have to refer to theory information about the possible circuit diagrams.

5.4 Why is this output needed for the ECU to properly run the engine? How do these outputs change how the engine runs in the different conditions of idle, part throttle cruise, and wide open throttle power?

When the throttle fully close or idle under roughly 15degrees, ECU receives battery voltage because reference voltage contact to idle terminal.When the throttle nearly 15degrees to fully open, ECU receives battery voltage because reference voltage contact to PSW terminal. In between, ECU will know the engine running cruise.

ECT (Engine Coolant Temperature) Sensor

6.1 With the engine Not running, back-probe a likely wire for the ECT supply by inserting a pin down the rubber insulation far enough to connect with the metal wire terminal on the inside. Do Not damage the wiring. Set up the voltmeter to read DC Volts. Attach meter red lead to the pin; attach black lead to a good ground.

6.2 Make sure all students and meter leads are clear of the engine. Turn the ignition “on”, but don’t start the engine.

6.3 Record the reading from the meter: 1.026V . If you do not get a reading on the meter, you may have to check for a good connection, or try different wires until you get a good reading to record above.

6.4 Is the engine cold, between cold and normal temperature (warming up), or at normal operating temperature? Normal operating Temperature.

6.5 Does the voltage reading above seem right for the temperature of the engine? Yes.

6.6 Make sure all students and meter leads are clear of the engine. Start the engine. Let the engine warm up for about two more minutes, and record the voltage of the ECT sensor now: 0.8V.

6.7 A warmer engine should usually show a lower voltage. Is the reading above lower than the first reading? Yes.

6.8 Describe how an ECT sensor works.

According the ECT characteristic, ECT is negative temperature coefficient. When is the engine cold condition, the voltage output will be high because the resistance high. And the engine warm the voltage will be going down because the resistance inside the sensor getting low. Specially when the engine very hot, the resistance very low and voltage output very low.

6.9 Describe how the ECT sensor voltage affects the fuel injection output from the ECU.

ECT sensor telling to the ECU that the injectors spray less or more fuel to the engine.

6.10 Describe what could go wrong to create an incorrect voltage for the ECU:

Possible running rich all the time /and overheat the engine.

6.11 Draw the circuit diagram for the ECT sensor for this vehicle. Include some detail inside the ECU.

Ground Coolant Temperature Sensor

7.1 Locate the ground or earth wire:

7.2 Back-probe the sensor ground or earth wire by inserting a pin down the rubber insulation far enough to connect with the metal wire terminal on the inside. Don’t puncture or damage the wiring. Hook up your multimeter red lead to read dc volts. Set the meter range or scale to 4V or less. Make sure the meter black lead is grounded on engine block or battery.

7.3 Make sure students and meter leads are clear of moving parts, and start the engine.

7.4` Record the voltage on the meter: 7.7mV. (A good ground will usually read less than 0.05V. Some manufacturers say 0.10V.)

7.5 What does this voltage tell you about the ECU earth or ground? Why is it important to measure it?

The ECU has a good earth. Because ECU will give the wrong voltage reading.

7.4 Discuss what could go wrong so that the ECU earth or ground is not good:

The ECU will process wrong signal and return back wrong signal to engine signals and hence affect engine performance.

RPM Sensor or Crank Position Sensor (CKP)

4.1 Locate the RPM sensor or Crank Position sensor for the vehicle or engine you are working on.Tested on 1ZZ engine.

4.2 With the engine Not Running, back-probe a RPM signal wire by inserting a pin down the rubber insulation far enough to connect with the metal wire terminal on the inside. Do Not damage the wiring.

4.3 Set up the voltmeter to read AC volts. Attach meter red lead to the pin; attach black lead to a good ground. Make sure the meter leads are clear of moving parts for when you start the engine.

4.4 Make sure all students are clear of the engine. Start the engine.

4.6 Increase engine RPM to about 2500 rpm. Record the reading from the meter: 5.6V

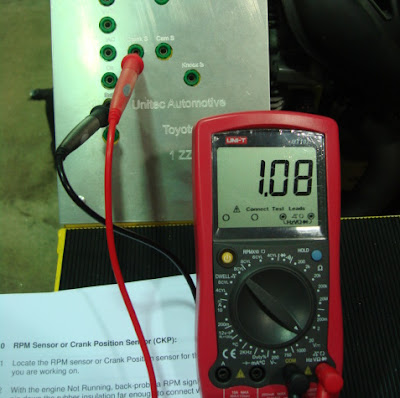

Record the reading from the meter: 0.568V.

4.9 Switch the voltmeter to read Hz. Record the reading from the meter: 503Hz.

4.11 Which setting best showed if the RPM sensor was working: Hz.

What type of RPM or Crank sensor is on your engine? Inductive pick-up.

4.12 Describe how this type of RPM or Crank sensor works:

Inside the distributor there are the teeth, the teeth give the induction to the magnet to produce the signal and telling to the ECU. When the teeth move away from the inductive pick-up the signal will be weak. 4.13 Discuss how using different functions of your meter can help you to accurately measure the sensor output when you don’t have an oscilloscope available?

Only using multi-meter, take RMS voltage available X 0.707. Or measuring by HZ scale and duty cycle.

4.14 What can go wrong so the ECU did not receive the correct signal from the RPM or Crank sensor: Wrong the RPM on the dashboard and the teeth inside the distributor will tell the ECU not correct angle of firing or misfiring.

4.15 Draw the circuit diagram for this RPM or Crank Position Sensor:

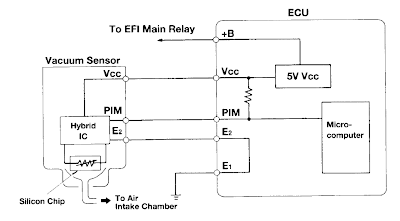

MAP Sensor

5.1 Locate the device on your engine that senses the engine load (the amount of air coming into the engine. Usually this is a MAP (Manifold Absolute Position) or MAF (Mass Air Flow) sensor.

For a MAP sensor follow these steps: (If you have a MAF sensor, go to the next section where is says “For a MAF sensor follow these steps”).

5.2 Locate the wire or wires likely to have the MAP input going to the ECM. You may have to use a wiring diagram or locator manual. Or you may have to just try different wires.

5.3 With the engine Not running, back-probe a likely wire for the MAP or MAF input by inserting a pin down the rubber insulation far enough to connect with the metal wire terminal on the inside. Do Not damage the wiring.

5.4 Set up the voltmeter to read DC volts. Attach meter red lead to the pin; attach black lead to a good ground. Make sure the meter leads are clear of moving parts for when you start the engine.

5.5 Make sure all students are clear of the engine. Turn the ignition “on”, but don’t start the engine.

5.6 Record the reading from the meter: 1.79V.

5.7 Make sure all students are clear of the engine. Start the engine. Let it idle.

5.8 Record the reading from the meter: 0.39V.

5.9 Step on the throttle to get quick, but short acceleration of the engine.

(Don’t rev the engine up too high.) Record the increased reading on the meter: 3.588V.

5.10 Describe how the MAP sensor works to tell the engine how much air comes into the engine?

The MAP sensor produce engine load signal to the ECU. If the engine load is higher means the vacuum is lower and vice-versa. The MAP sensor can read both vacuum and pressure. When the vacuum increase, the voltage output decrease, and when the pressure increase, the voltage output increase.

5.11 Discuss how the readings above are correct or incorrect for this engine:

Correct. All reading above telling us that lower negative pressure or vacuum inside intake manifold the higher voltage reading. When the engine at idle speed, the vacuum in the manifold is maximum, the reading should be lowest. When the engine at acceleration, the vacuum in the manifold is decreased, the reading should be increased.

5.12 What could go wrong so the ECU did not receive the correct signal from the MAP sensor?

The Ecu will sending wrong signal to the injectors. And the injector not spraying exactly amount of engine needs.

5.13 Draw the circuit diagram for the MAP sensor on this engine in the box below:

MAF sensor

Tested MAF sensor only on the range rover engine. MAF sensor have 5 wires:

- Temperature Sensor: 2V

- Signal to ECU: 1.44V

Set the multi-meter to Hz and turn the key On: 0Hz

Start the engine at idle position: 0Hz

This video showing short acceleration in Hz scale.

From pictures and a video above they are showing correctly because when ignition key on and idle position reading 0Hz. There was stable voltage to ECU. And the engine revv in short period, the frequency rise up in the mean time more air coming in.

The Ecu will sending wrong signal to the injectors. And the injector not spraying exactly amount of engine needs.

9.0 IAT (Intake Air Temperature), ACT (Air Charge Temperature), or MAT

(Manifold Air Temperature Sensor)

9.1 Locate the IAT type sensor on your vehicle.

9.2 With the engine Not running, back-probe a likely wire for the IAT input by inserting a pin down the rubber insulation far enough to connect with the metal wire terminal on the inside. Do Not damage the wiring. Set up the voltmeter to read DC Volts. Attach meter red lead to the pin; attach black lead to a good ground.

9.3 Make sure all students and meter leads are clear of the moving parts of the engine. Turn the ignition “on”, but don’t start the engine.

9.4 Record the reading from the meter: 2.067V. If you do not get a reading on the meter, you may have to check for a good connection, or try different wires until you get a good reading to record above.

9.5 Is the reading more or less than the reading you had for the ECT? More.

Does this show the IAT sensor is colder or hotter than the ECT sensor? Colder.

9.6 Describe how the IAT sensor works.

IAT is negative temperature coefficient(NCT) where is the temperature getting hot the resistance getting lower and voltage getting lower. And vice-versa.9.7 Describe how the IAT reading affects the ECU outputs for fuel injection. Include how an incorrect input could affect the fuel injection and engine running:

As the air is more dense when cold, so the engine will run lean in this condition. IAT sensor sends the signal for this by mean of voltage variation to ECU. ECU then process it for fuel correction program and make the fuel adjustment accordingly so that the engine running in closed loop.

9.8 Describe how the IAT sensor signal should change for different air temperature conditions;

IAT sensor have same resistance characteristics with water temperature. When high temperature it will send the low voltage to ECU and in cold condition when air is dense (more air going inside intake manifold), it will send high voltage to ECU.

9.9 Describe what could go wrong to create an incorrect IAT signal for the ECU:

The engine will be running rich or lean depends on the signal received by ECU.

9.10 Draw the wiring diagram for the IAT sensor for this vehicle. Include some

detail inside the ECU.

Camshaft Position Sensor (CMP)

10.1 Locate the Camshaft Position Sensor on a vehicle. This may be near the camshaft or it may be in the distributor.

10.2 Locate the wire that carries the signal to the ECU. Back probe the wire to measure the signal. Experiment with different settings on your multimeter to see which best indicates that the CMP signal is good. (DC volts, AC volts, HZ, or % Duty Cycle)

10.3 Record your meter readings below in the different settings, and discuss which settings show the CMP is good.

DC Volts: 3.1mV G- G1 DC Volts: 76.3mV NE+ NE-

AC Volts:129.3mV G- G1

AC Volts: 0.772V NE+ NE- HZ (hertz): 0.075KHz G- G1

HZ (hertz): 0.038KHz NE+ NE-Duty Cycle: 3.8% G- G1

Duty Cycle: 9.3% NE+ NE-

The good setting is using the oscilloscope measuring in the Hz scale. E.g below:

G pick-up waveform:

Ne pick-up waveform:

10.4 Draw the circuit diagram for the Cam Position Sensor on this vehicle:

This comment has been removed by the author.

ReplyDeleteOn your ECT and IAT you have got the resistance the wrong way around the ECT/IAT resistance is high when cold requiring a higher voltage to cross it and when warm the resistance is low requiring a low voltage to cross it. It is a voltage divider and remember a NTC thermistor.

ReplyDeleteYou forgot to change your readings from your MAF sensor remember that the EMF from the Drive by wire unit were you had your ground interfered with the signal

Oh, Ok I got it, I fixed. Thank you.

ReplyDelete